YOUR SPARKLING WINE,

WITH YOUR WINE,

IN YOUR CELLAR

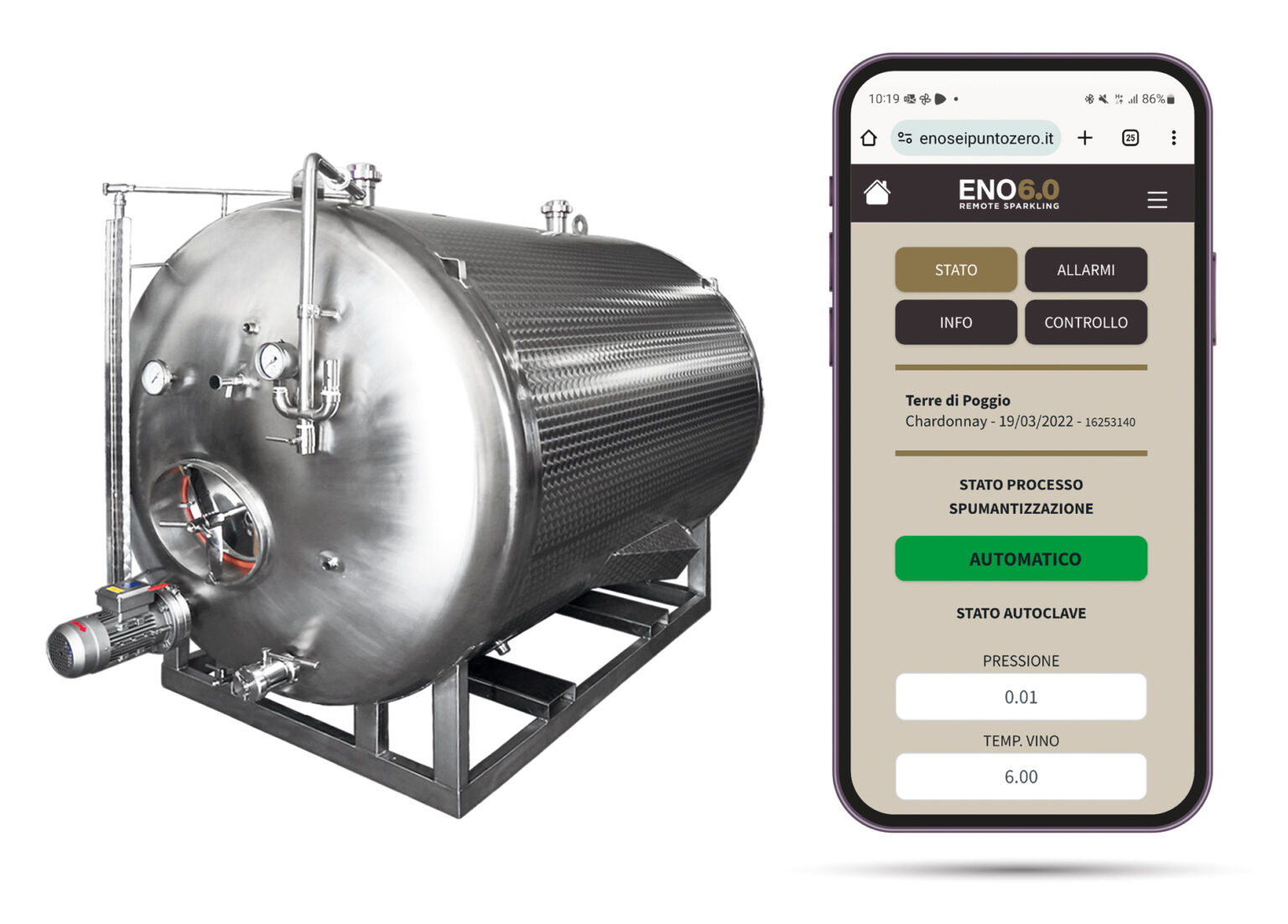

ENO6.0 is the solution that brings the know-how and equipment needed for sparkling wine making to the winery, from the autoclave for frothing, to the isobaric filtration system, to the bottling line with in-line capsuling, centering and labeling.

This system offers many advantages:

- Since the product never leaves its place of origin, the inconvenience and costs associated with transportation required for sparkling at a third party are eliminated. This ensures total control over the supply chain, quality and sustainability of the sparkling wine.

- Our specialized team offerscomprehensive technical assistance at all stages of sparkling wine making to achieve a process that is always under control and high quality results, guaranteeing the producer certain costs without surprises and eliminating any possible unforeseen variables.

- Enotech’s innovative isobaric filtration technology makes it possible to produce a sparkling wine without the addition of sulfites, meeting the growing market demand for increasingly natural and healthy products.

- With the indication of “sparkling wine processed at origin and in its entirety,” the label testifies to the authenticity and excellence of the product and allows the designation to be maintained, ensuring the highest quality and recognition of added economic value by consumers.

WHY SPARKLING WINE

In the world wine market, sparkling wines account for 18 percent of the total. Over the past 10 years, sales of sparkling wine have grown by an average of 90 percent. In Italy, 750 million bottles of sparkling wine are produced each year and domestic consumption is currently 180 million bottles, of which 160 million are Charmat Method.

Traditionally, wineries that want to sparkle their wine have two options available to them:

- Set up your own production line by purchasing expensive equipment and training your own staff. This option is justified only when there is a high volume of production.

- Carry out the sparkling process at a third party, incurring the necessary transportation costs. In this case, it is difficult to exercise control over the entire production chain, and off-site bottling must be reported on the label.

These considerations and the “mobile” philosophy of Enotech Wine Service, prompted us to design and implement a solution that offers wine producers large and small the opportunity to carry out the Charmat method sparkling process directly in their own winery.

WITH YOUR WINE AND OUR INNOVATIVE SOLUTIONS,

EVIL THAT GOES.

WILL BE A SUCCESS

“If we know how to make cars in this country, we must also know how to make gasoline.”

E. Mattei

The “Domenico Rocco Monticelli” is part of the painstaking and meticulous work done through testing and prepackaging that led to the current ENO6.0 solution.

EVERYTHING ALWAYS

UNDER CONTROL

One of the strengths of the ENO6.0 system is its flexibility, allowing each stage of the sparkling wine process to be customized to the specific needs of the wine and grapes used, enabling a wide range of styles and characteristics, tailored to consumer tastes and preferences.

To achieve this goal, it is essential to have precise control over all production parameters to ensure predictable and repeatable results.

In addition to control directly from the panel, thanks to a specific App, it is possible to keep the status of the autocalve constantly monitored remotely, such as power on, power off, stirrer status, temperature and pressure, and, if necessary, intervene on the set parameters.

Access to the application is provided at the installation of the autoclave so that the winery manager, his winemaker, and the staff employed in production can control every step of the sparkling process.

Enotech’s technicians ensure, in real time, control support and remote intervention. The system implements an automatic alert sending function in case of non-compliant parameters.

FOCUS

THE CHARMAT METHOD

The ‘Italian Method’ or Charmat is one of the main systems used in our country for the production of sparkling wines widely appreciated all over the world.

The sparkling process begins withblending (cuveé) by blending wines produced from different grape varieties or different vintages. Next, the base wine is transferred to a temperature-controlled autoclave, where selected yeast, sugar and minerals are added to trigger secondary fermentation.

At this stage, the yeasts consume the sugar and produce carbon dioxide as a byproduct. As the autoclave is sealed, the pressure increases and carbon dioxide dissolves into the wine, creating frothing or tirage.

Once secondary fermentation is complete, the wine is chilled and filtered. Finally, the sparkling wine is bottled, sealed using a special bottling machine that does not let the wine lose pressure, and left to age for a variable period of time.